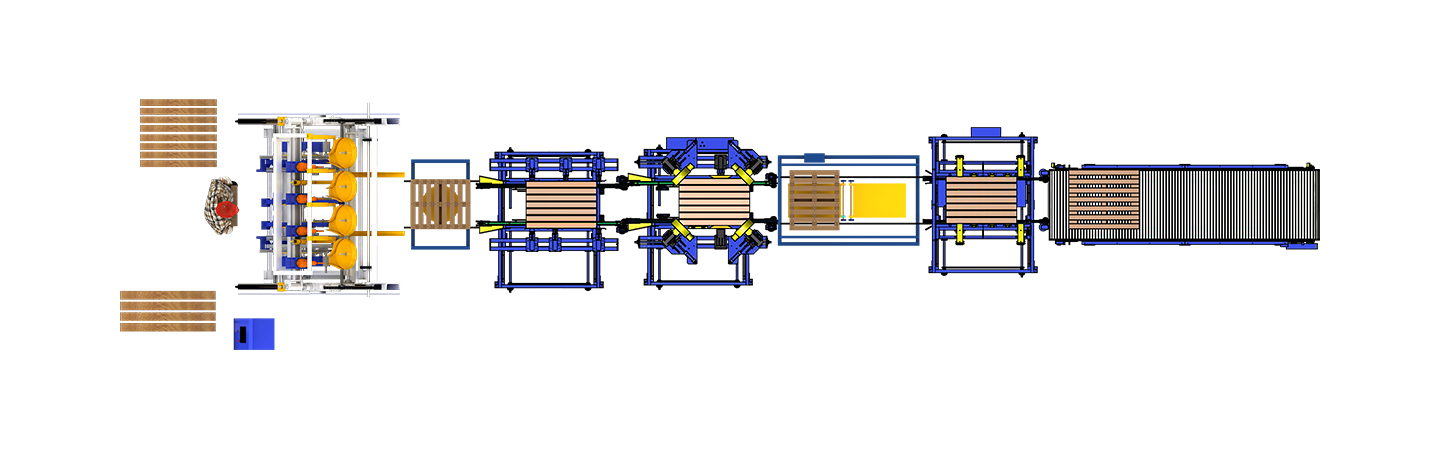

Umatshini wokubethelela ipalethi yeplanga ye-CNC Iinkcukacha:

Ukuqaliswa komatshini wokubethelela ipalethi yamaplanga

Umatshini wokubethelela ipalethi yomthi ozenzekelayo usetyenziswa ikakhulu kwimveliso yeepaliti zaseMelika naseYurophu.Umatshini wethu wokubethelela ipalethi uxhotyiswe ngesixhobo sokuguqula i-pallet kunye nesixhobo se-palletizing, inqanaba eliphezulu lokuzenzekelayo.Umatshini wonke uthatha ulawulo lweprogram oluzenzekelayo, inkqubo yokusebenza ithatha i-PLC evela kumazwe angaphandle.Inkampani yethu yenze uphuculo oluninzi kumatshini wokubethelela ipalethi yamaplanga, kwaye ixabiso lomatshini wokubethelela ipali liphantsi.Umatshini usebenza ngokuzinzileyo kwaye unokuqhubeka ngokuqhubekayo nangokufanelekileyo.

Umgaqo osebenzayo womatshini wokubethelela ipalethi yokhuni

I-automatic wood pallet ukubethelwa komatshini sisixhobo esibalulekileyo sokudibanisa umthi we-pallet.Umsebenzi uya kubeka ipleyiti eboshiweyo kumatshini we-pallet yomntu omnye, kwaye umpu we-nail uya kuhamba ngokuzenzekelayo phantsi kwe-drive ye-servo motor ukwenza izikhonkwane.Emva kokugqitywa kwe-napping, umatshini we-palletizing oxhotyiswe ngasemva komatshini uya kuziphalisa ngokuzenzekelayo.Yonke inkqubo inokuqhutywa ngesikrini sokuchukumisa, kwaye inkqubo ilawula ngokuzenzekelayo isikhonkwane, isantya sompu wesikhonkwane samaxesha angama-4 ngomzuzwana, okuyi-3 amaxesha encwadana.Yonke inkqubo yokondla ngesandla, ukubethelwa ngokuzenzekelayo, ukupakisha ngokuzenzekelayo.

Iiparameters zobuchwephesha bomatshini wokubethelela

Ukulungiswa komatshini wokubethelela ipalethi

Xa umatshini wezikhonkwane usebenza, umntu kufuneka abeke ibhodi yeenkuni ezisarhiweyo kumatshini wokubethelela, aze aqalise iqhosha lokutshintsha lomatshini wokubethelela, aze umatshini awugqibezele ngokuzenzekelayo wonke umsebenzi wokubethelela.Xa izixhobo zokubethelela iiplanga zeplanga zisebenza, indawo yokubethelwa iyafana, ubunzulu buyafana, kwaye impazamo ingaphantsi kwe-1 mm.Uyilo lomatshini lugqwesileyo, ukusebenza okuzinzileyo, isakhiwo esihle kakhulu.Inokuxhotyiswa ngesikhonkwane esivuzayo, isixhobo sokubona iinzipho ezingenanto.Ukugcina ixesha, ukonga abasebenzi, imisebenzi emininzi.

Inzuzo yomatshini wokubethelela ipalethi

1. ukusetyenziswa komlawuli oqeqeshiweyo, kunye nesoftware exhasayo eyenziwe ngokwezifiso, ukusebenza ngokukhuselekileyo kunye nokuzinza, ukusebenza kakuhle kwemveliso.

2. ukusetyenziswa kwe-servo motor kunye nokuchaneka kwe-servo reducer: ukuchaneka kokusebenza komatshini kuphezulu, ukuqinisekisa ukuba ubungakanani bokusebenza buhambelana.

3. Iyakwazi ukucubungula iipaliti eziqhelekileyo zaseMelika kunye neepaliti eziqhelekileyo zaseYurophu, zinokuthi zenziwe ngokwezifiso iipaliti ezingezizo eziqhelekileyo.

4. Umsebenzi ulula, umntu omnye unokusebenza.Ukutya ngesandla, isikhonkwane esizenzekelayo, i-automatic palletizing.

5. Ukusebenza kwesikrini sokuchukumisa, inkqubo yokulawula isikhonkwane esizenzekelayo, isantya sompu wesikhonkwane ngamaxesha e-4 / isibini, isantya sokutya iiyure ezingama-400 / 8, ngamaxesha e-3.